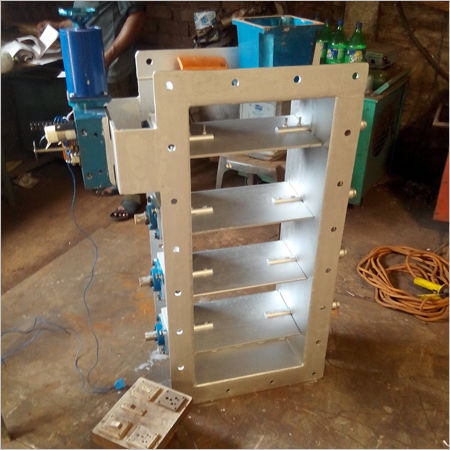

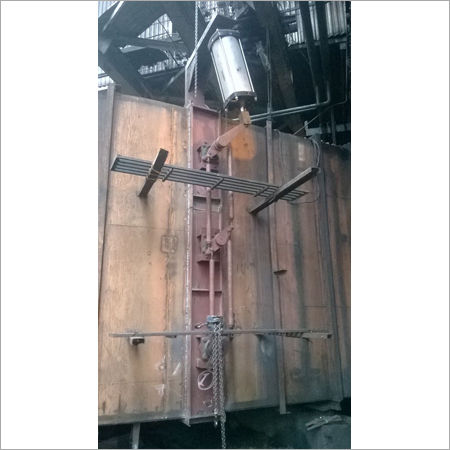

High Temperature Dampers

10000 INR/Set

Product Details:

- Features Corrosion resistance, Sturdy design, Efficient performance, Negligible maintenance

- Surface Treatment Powder Coated

- Usage Industrial

- Type High Temperature Dampers

- Material Galvanized Iron (GI) / Mild Steel (MS)

- Size Different sizes available

- Color Silver

- Click to View more

X

High Temperature Dampers Price And Quantity

- 10000 INR/Set

- 2 Set

High Temperature Dampers Product Specifications

- Galvanized Iron (GI) / Mild Steel (MS)

- Industrial

- for modulation of vapor flows in various types of applications.

- Different sizes available

- Corrosion resistance, Sturdy design, Efficient performance, Negligible maintenance

- High Temperature Dampers

- Silver

- Powder Coated

High Temperature Dampers Trade Information

- 10-15 Set Per Month

- 1 Months

- Asia, Australia, South America, Western Europe, Middle East, Central America, North America, Africa, Eastern Europe

- All India

Product Description

The high temperature dampers are used for controlling the flow of radioactive gases in nuclear power plants but can be used for other applications in many industries. They have a temperature limit of five hundred degrees. The offered damper has the use in controlling the high temperatures and is used for many manufacturing processes. The damper is made of high grade metal for bearing high temperature yet work effectively. The High temperature dampers are used for effective working of many industries and are very safe to use and install. The Dampers are made for the multipurpose applications.

Engineered for Performance

Designed for industrial environments, our High Temperature Dampers are built to withstand extreme conditions while maintaining efficient and reliable vapor flow regulation. Their sturdy construction and high-quality powder coating ensure long-lasting performance, even in the harshest applications.

Versatile Application and Design

Whether you require dampers for power plants, chemical processing, or other industrial settings, our products cater to various applications with ease. Available in multiple sizes and manufactured from GI or MS, they adapt seamlessly to specific project needs, providing both flexibility and dependability.

Low Maintenance Solutions

Thanks to their corrosion-resistant finish and robust design, these dampers require negligible maintenance over time. This not only reduces operational disruptions but also helps keep long-term ownership costs low, making them a cost-effective choice for industrial users.

FAQs of High Temperature Dampers:

Q: How are High Temperature Dampers used in industrial applications?

A: High Temperature Dampers are primarily used to modulate vapor flows in a wide range of industrial processes. They control and direct vapor movement within systems, ensuring precise flow regulation to meet specific process requirements.Q: What materials are High Temperature Dampers made from?

A: These dampers are manufactured using Galvanized Iron (GI) or Mild Steel (MS). The choice of material ensures robust strength, durability, and reliable performance under high temperature conditions.Q: Where can High Temperature Dampers be installed?

A: They are suitable for installation in various industrial settings, including factories, power plants, chemical facilities, and other environments where control of high temperature vapor flow is essential.Q: What is the surface treatment process for these dampers?

A: All High Temperature Dampers undergo a powder coating process, which enhances their resistance to corrosion, provides a uniform silver finish, and significantly extends their service life.Q: When should High Temperature Dampers be used?

A: These dampers are ideal when your application demands efficient, precise, and continuous modulation of vapor flows in high temperature environments. Their sturdy design also makes them suitable for usage in settings that demand robust and reliable components.Q: What are the main benefits of using High Temperature Dampers?

A: Key benefits include outstanding corrosion resistance, minimal maintenance requirements, efficient performance, and a sturdy structure that guarantees longevity and safety in demanding industrial processes.Q: How does the design of these dampers contribute to their efficiency?

A: The combination of sturdy, powder-coated GI or MS materials ensures that the dampers operate smoothly with minimal wear, while their robust construction reduces the need for frequent upkeep, thereby maximizing operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email