Welcome to Our Company

Talk with Expert :

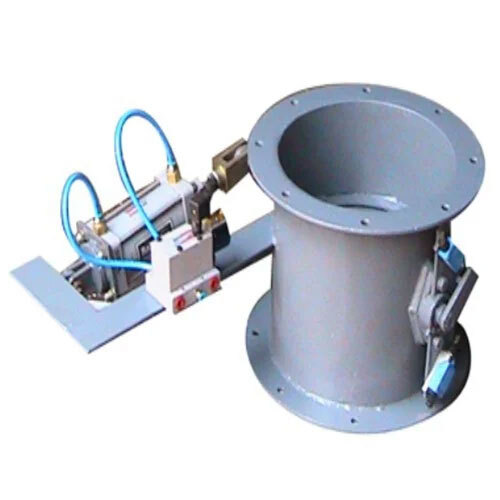

Pneumatically Operated Damper

10000 INR/Set

Product Details:

- Automation Grade Automatic

- Surface Treatment Powder Coated / Painted

- Features Low Leakage, Robust Construction, Reliable Performance

- Control System Pneumatically Controlled

- Operating Pressure 4-6 Bar

- Technology Pneumatic Actuation

- Accessories Type Actuator, Pneumatic Cylinder

- Click to View more

X

Pneumatically Operated Damper Price And Quantity

- 10000 INR/Set

- 2 Set

Pneumatically Operated Damper Product Specifications

- Duct Damper

- Compressed Air

- High Positioning Accuracy

- Airflow Regulation

- Mild Steel / Galvanized Steel

- 4-6 Bar

- Pneumatic Actuation

- HVAC Systems, Industrial Ventilation

- Not Applicable (Pneumatic Driven)

- Actuator, Pneumatic Cylinder

- Powder Coated / Painted

- Automatic

- Pneumatically Controlled

- Low Leakage, Robust Construction, Reliable Performance

- Air Control Damper

Pneumatically Operated Damper Trade Information

- 10-15 Set Per Month

- 1 Months

- North America, South America, Australia, Eastern Europe, Middle East, Central America, Africa, Asia, Western Europe

- All India

Product Description

The Pneumatically operated damper is made for the controlling of air flow in various cooling and heating systems. It is easy to operate and install and can help in effective control over the flow of air in air conditioners in the unused rooms. The effective air controlling is required for the correct cooling and heating in offices, commercial places etc. The pneumatically operated dampers are made of high quality metal that is long lasting and free from any abrasion, corrosion or rust. It has a sleek design and size that is fit for use in any building

Precision Airflow Regulation for Demanding Environments

Constructed for automated and accurate airflow management, our Pneumatically Operated Dampers are ideal for HVAC and industrial settings where low leakage and high reliability are essential. The custom-size options fit a wide range of duct applications, and their powder-coated or painted surfaces provide durable, corrosion-resistant protection even in challenging climates.

Custom-Built Solutions with Versatile Mounting and Actuation

Whether you need flanged or slip-in mounting, our dampers are engineered for quick installation with standard duct connections. The selection of opposed or parallel blade designs allows you to tailor the performance to specific airflow requirements, all while benefiting from a robust pneumatic actuation system powered by compressed air.

FAQs of Pneumatically Operated Damper:

Q: How is a pneumatically operated damper installed in HVAC or ventilation ducts?

A: These dampers are designed with either flanged or slip-in mounting, fitting seamlessly onto standard duct interfaces. Installation is straightforward and can be handled by HVAC professionals using common industry practices.Q: What advantages does pneumatic actuation offer compared to electric or manual dampers?

A: Pneumatic actuation delivers rapid and precise control, enabling high positioning accuracy and automated airflow regulation. It is highly reliable in industrial environments and requires no electrical poweronly compressed air.Q: When should I consider using opposed or parallel blade designs?

A: Opposed blade designs are ideal for even airflow distribution and fine control, while parallel blades are suited for applications requiring higher flow rates. The choice depends on the specific air management requirements of your system.Q: Where can these dampers be used effectively?

A: These dampers are well-suited to HVAC systems, industrial ventilation, and machine ducting in commercial or manufacturing facilities. Their versatility and customization make them suitable for a broad range of applications.Q: What process is involved in the maintenance of this pneumatic damper?

A: Maintenance is minimal due to the robust construction and quality surface treatment. Simple periodic checks for actuator performance and occasional cleaning are generally sufficient to ensure reliable operation.Q: What benefits will I gain by using a corrosion-resistant, powder-coated or painted damper?

A: The corrosion-resistant finish prolongs the dampers lifespan, even in humid or chemically active environments, reducing the need for replacement and ensuring consistent performance over time.Q: How is the maximum allowable damper size determined for my application?

A: While standard sizes go up to 2000 mm x 2000 mm, dampers can be custom-built to meet unique duct requirements. The appropriate size is determined by your airflow needs and ductwork specifications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email