स्वचालित लौवर डम्पर

उत्पाद विवरण:

- सटीकता High sealing and air control precision

- ऑपरेटिंग प्रेशर Standard HVAC operating pressures

- कंट्रोल सिस्टम Electric / Pneumatic actuator

- मशीन का प्रकार Air Control Damper

- सहायक उपकरण का प्रकार Actuators, Linkages, Mounting Brackets

- टेक्नोलॉजी Automatic Operation

- सतह का उपचार Powder Coated / Galvanized

- अधिक देखने के लिए क्लिक करें

स्वचालित लौवर डम्पर मूल्य और मात्रा

- , सेट/सेट्स

- शीट/शीट्स

- 2

स्वचालित लौवर डम्पर उत्पाद की विशेषताएं

- Electric / Pneumatic

- Automatic

- Corrosion resistant, Smooth operation, Low leakage, Robust construction, Easy installation

- Powder Coated / Galvanized

- Automatic Operation

- Mild Steel / Galvanized Steel / Stainless Steel

- Louver Damper

- HVAC systems, Industrial ventilation, Exhaust applications

- Electric / Pneumatic actuator

- Air Control Damper

- 220-240V AC (for electric actuators)

- Actuators, Linkages, Mounting Brackets

- High sealing and air control precision

- Standard HVAC operating pressures

- Regulates and controls airflow in ventilation systems

स्वचालित लौवर डम्पर व्यापार सूचना

- पश्चिम बंगाल

- 10-15 प्रति महीने

- 1 महीने

- स्टैंडर्ड पैकेजिंग

- पश्चिम बंगाल, ऑल इंडिया

- आईएसओ 9001: 2008

उत्पाद वर्णन

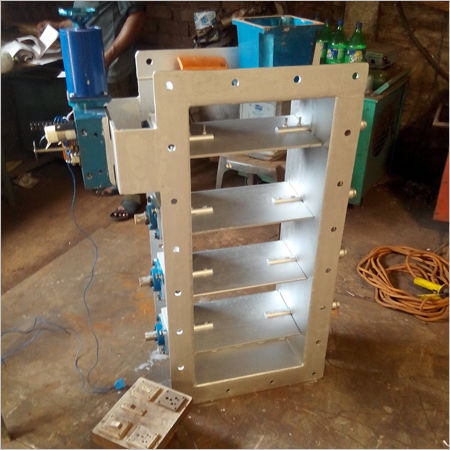

Louvers Damper

On a gas conduit system, the assembly between flanges is handled by the Automatic Louver Damper. Louver dampers are made by using different opposed or parallel blades that allow ideal regulation, opening times and good closure. The standard model offered by VALVETEK is designed to operate at around 500 mbar pressures, and the recommended temperature is about 800ºC and speeds of below 30m/s. Closing degree range of 90%-99% of this relatively air tight valve can reach 100% on the introduction of an air sealing system. Designing of the standard Automatic Louver Damper model is done in a manner to maintain a horizontal position of the drive shafts. Although, option for vertical position assembly of the shafts is also possible as per demand.

Standard Louver DamperSeveral blades, rotating on the central shaft are fitted on the louver damper. Ends of these blades are joined to the conduits by the help of flanges. The louver damper is basically supplied as an individual part, leaving out the applications in which the unit dimensions need special transport.

Seating Options:Depending on the application, the louvers have two different types of seal design, the options are: swing-thru (closure from 90% to 97%) for surroundings with a density of dust (of below 1000 mg/Nm3); and the closure of 99% for step seat suitable for other applications needing top level of air insulation.

Bearing:Louvers supplied by VALVETEK have bearings located on the outside and detached from the packing. By following this way, they are kept safe from sources which can cause corrosion and heat, hence enhancing their operational life. This system also enables the packing change without any need to remove the bearing, which leads to easier future maintenance jobs.

Construction:Different material can be utilized in the fabrication of the body of the louver dampers. Size range for the standard construction includes 150x1500 mm (min) to 2000x2000 mm (max). Although, larger sizes can be constructed as per request. Reinforcing ribs are used for the construction of blades and are backed by two semi-shafts. Ideally rigid flat disc system withstands the operational pressures caused on these valves and does not cause major losses.

Insulation:VALVETEK offers its valves ready for 200 mm outer insulation. A space is provided for changing bearings and packings in the future without removing the insulation furnished.

Louver Damper with Sealing System Two parallel louvers are used in the making of louver damper with sealing system. In the space between the fitted louvers, the seal is created to inject ambient air comparatively more pressure than that of the gases flowing in the passages. A pressurized chamber is created by this system, which stops gases from leaking. This therefore ensures the air tightness of the valve with the passages. Design of this system is ideal for withstanding pressures below 250 mmwc. Electroventilator, a sealing valve, a sealing pipe and a dilation compensator are used in the making of the sealing system. Other features are just the same as the standard louver damper without sealing system.

उत्पाद विवरण

| Frequency | 50 HZ |

| Corrosion Resistance | yes |

| condition | new |

| Power Source | Electric |

| Max ambient temperature | 60 degree C |

| Material | MS |

Robust & Versatile Construction

Choose from a range of blade and frame materialsaluminum, galvanized steel, or stainless steelensuring high durability for diverse environments. The heavy-gauge extruded options enhance structural integrity, while surface treatments like powder-coating and anodizing offer strong resistance against corrosion, making this damper ideal for challenging industrial and HVAC settings.

Precision Airflow Management

The dampers opposed or parallel blade operation provides high accuracy in controlling airflow. Its low-leakage design minimizes energy losses, contributing to improved efficiency in ventilation systems. Coupled with high-quality seals and precise actuation, the damper ensures tight sealing and optimal performance even under fluctuating pressure conditions.

Easy Installation & Effortless Maintenance

With flange or duct-mounting options, installation fits a wide array of setups. Maintenance is greatly simplified by the dampers thoughtful design, which allows straightforward access for servicing. The sturdy construction and smooth operation mean minimal wear over time, reducing downtime and maintenance costs.

FAQs of Automatic Louver Damper:

Q: How does the automatic louver damper regulate airflow in ventilation systems?

A: The damper uses opposed or parallel blade action, operated by electric or pneumatic actuators, to precisely control the volume and direction of air passing through HVAC or industrial ducts. This automation ensures efficient air distribution and regulation without manual adjustments.Q: What are the available size and finish options for the automatic louver damper?

A: Sizes start at 100mm x 100mm and can be customized to fit project-specific needs. Finish options include epoxy coating, anodized surfaces, powder coating, and other custom treatments, providing enhanced durability and corrosion resistance for various environments.Q: When should I consider using an automatic louver damper in my ventilation project?

A: Automatic louver dampers are ideal when precise, consistent airflow control is required, especially in large or variable-load HVAC systems, industrial ventilation, and exhaust applications where automated adjustment is beneficial for energy savings and comfort.Q: Where can these dampers be installed, and what mounting options are available?

A: They are suitable for installation in commercial, industrial, and institutional HVAC systems. The damper can be flange-mounted or duct-mounted to accommodate different system layouts and preferences, ensuring versatile application.Q: What is the maintenance process for the automatic louver damper?

A: The damper is designed for minimal maintenance. Its accessible structure allows for easy inspection and servicing of moving parts and actuators, extending lifespan and minimizing system downtime.Q: How do the design features benefit my ventilation system?

A: Low leakage levels, precision engineering, and robust construction provide energy efficiency, reliable sealing, and long operational life. Corrosion resistance and easy installation further increase the dampers value and reduce maintenance costs.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें